Markets - Electrical

Thermoset Composites Add Structural and Dielectric Capabilities to Electrical Equipment

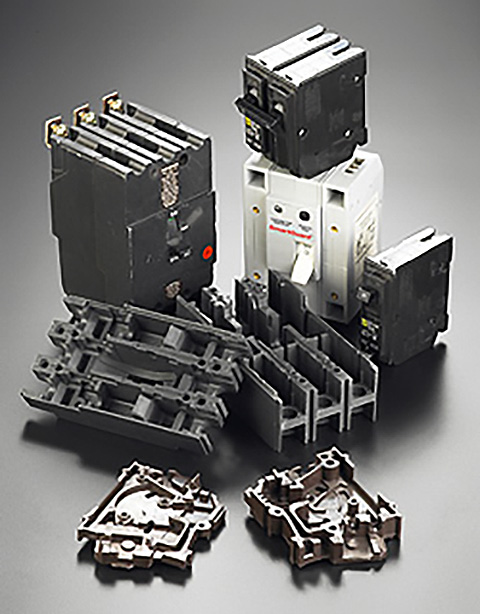

Superior electrical insulation, heat resistance, and dielectric properties make sheet molding compounds (SMC), bulk molding compounds (BMC), and new lines of high performance composites (Ultrium, Fortium, Flamevex and Alluralite) that are manufactured for the most demanding applications the right choice for insulating components of switch gear, circuit breakers, stand off insulators, and motor brush holders.

UL Rated Thermoset Composites for Electrical ApplicationsThermoset composite materials exhibit excellent dielectric strength due to the network of cross-linked molecules that create a rigid structure, where molecules are held in place by chemical bonds. Compounds made with thermoset binders, therefore, maintain both physical and electrical properties under mechanical loads during prolonged exposure to elevated temperatures.

UL Rated Thermoset Composites for Electrical ApplicationsThermoset composite materials exhibit excellent dielectric strength due to the network of cross-linked molecules that create a rigid structure, where molecules are held in place by chemical bonds. Compounds made with thermoset binders, therefore, maintain both physical and electrical properties under mechanical loads during prolonged exposure to elevated temperatures.

Often, parts molded from plastic materials will carbonize or melt during exposure to electrical arcing or tracking. However, thermoset composites for electrical applications demonstrate minimal effects in these situations and have Comparative Tracking Index (CTI) values exceeding 600 volts and dielectric strength in excess of 15 kv/mm. This, along with excellent thermal properties, makes SMC, BMC and IDI’s and new lines of high performance composites (Ultrium, Fortium, Flamevex and Alluralite) that are manufactured for the most demanding applications an ideal choice to protect sensitive electrical devices operating in high-temperature environments.